In today's competitive landscape, industrial manufacturing automation has emerged as a game-changer. According to Dr. Sarah Mitchell, an authority in automation technologies, "Automation not only boosts efficiency but also transforms the way we perceive manufacturing processes." This encapsulates the transformative potential of automation.

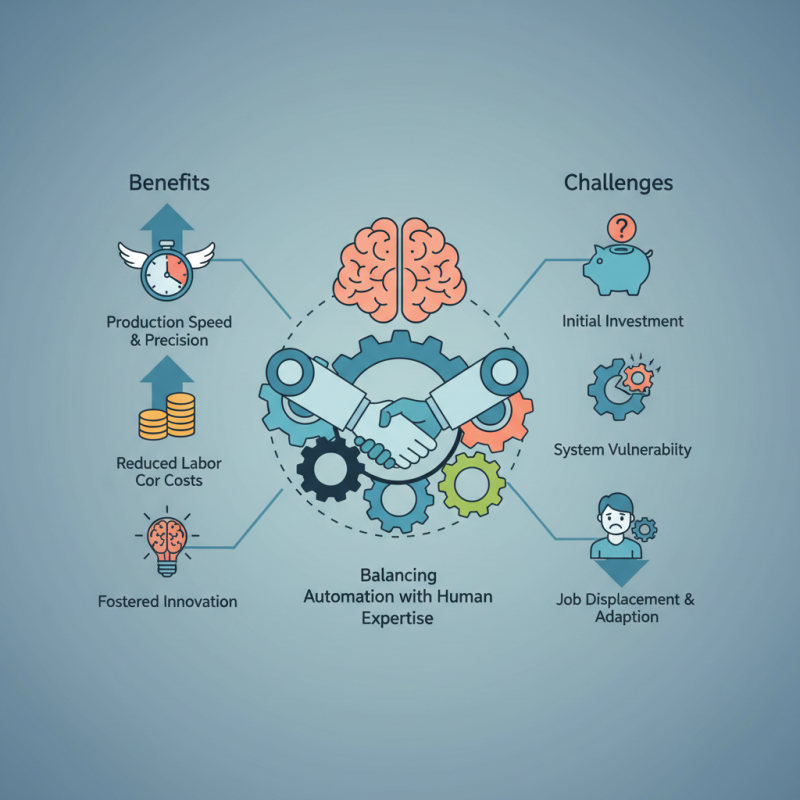

The adoption of industrial manufacturing automation brings numerous advantages. It enhances production speed and precision while reducing labor costs. Companies can reallocate human resources to more creative tasks, fostering innovation. However, this shift also raises concerns about job displacement. Workers need to adapt to new skill sets, which isn’t always straightforward.

Despite its benefits, industrial manufacturing automation requires careful consideration. The initial investment can be daunting for some firms. Furthermore, reliance on technology can lead to vulnerabilities. Systems might fail, impacting production. As businesses navigate these challenges, the focus should be on balancing automation with human expertise for optimum outcomes.

Industrial manufacturing automation brings significant advantages to various sectors. One major benefit is increased efficiency. Automated systems perform repetitive tasks quickly and accurately. This reduction in manual labor leads to faster production cycles. Workers can focus on more complex issues, enhancing overall productivity.

Another key advantage is consistency. Machines produce products with high precision. This minimizes errors and ensures uniform quality across batches. However, relying heavily on automation can create challenges. For instance, unexpected machine failures may cause delays. Companies must maintain equipment regularly to avoid these pitfalls.

Cost reduction is yet another positive aspect. Automation can lower operational costs over time. Fewer employees are needed for basic tasks, leading to savings on wages. Still, the initial investment in automation technology can be high. Companies should carefully assess their budget before making decisions. Balancing automation with skilled labor remains crucial in this evolving landscape.

This chart illustrates the key advantages of industrial manufacturing automation, highlighting improvements in efficiency, quality, and cost savings.

Industrial manufacturing automation significantly enhances efficiency and productivity. By implementing automated systems, companies can streamline operations. Tasks that once took hours can now be completed in minutes.

One of the key benefits is precision. Automated machines can execute tasks with incredible accuracy. This reduces the likelihood of errors and waste. However, teams must ensure that maintenance is prioritized. A small oversight can lead to costly downtime.

Tips: Regularly check the performance of your automated systems. Establish a proactive maintenance schedule. Also, invest in training for operators to maximize equipment usage. Proper training fosters a better understanding of the technology.

Another aspect to consider is adaptability. Automated processes can be adjusted for different products. This flexibility allows companies to respond quickly to market changes. Yet, it also requires ongoing assessment of production needs. Keeping an eye on trends is crucial.

Tips: Stay updated with industry advancements. Implement feedback loops to enhance automation strategies. Engage employees for their insights on daily challenges. Their experiences can highlight areas for improvement.

Industrial manufacturing automation has transformed production processes, leading to significant cost reductions. According to a recent McKinsey report, companies can save up to 30% in operational costs by leveraging automation technologies. These savings stem from increased efficiency and reduced labor costs. Automation minimizes the need for manual labor, thus allowing for reallocating resources to other critical areas.

Despite these advantages, the transition to automation can be challenging. Not all operations are ripe for automation, and some processes may require a hybrid approach, blending manual and automated systems. A survey by Deloitte found that 56% of manufacturers face issues with employee resistance to automation. While robotic systems streamline production lines, they can create disruptions if not integrated carefully.

Moreover, automation requires upfront investment. A lack of proper planning may lead to cost overruns. Automation solutions should not only focus on initial savings but also on long-term operational efficiency. For some businesses, the return on investment may take longer than expected. Continuous assessment is essential to ensure the benefits of automation align with the company’s strategic goals.

In today’s competitive landscape, improving product quality and consistency is paramount. Automation in industrial manufacturing plays a crucial role in achieving this. Machines, when programmed correctly, can operate with precision. They minimize human error, which often leads to inconsistencies in product output. For instance, a single automated line can ensure that each item produced meets the same exact specifications every time.

However, automation does not come without challenges. Regular maintenance is essential to prevent breakdowns or deviations in quality. An automation system might function perfectly for weeks, but a small glitch can lead to significant quality issues. It’s important to regularly audit the process and evaluate the output against quality standards.

Moreover, training staff to monitor and interact with automated systems can be complex. Employees may sometimes struggle to adapt to new technologies. This transition period can temporarily affect the consistency of products. Striking a balance between automation and human oversight is essential for optimal performance. Fine-tuning this relationship can lead to a remarkable improvement in overall product quality, fostering greater customer satisfaction.

In automated manufacturing environments, worker safety experiences a significant boost. With machines handling heavy lifting, the risk of injuries decreases substantially. Workers are less exposed to hazardous conditions. For instance, robotic arms can operate in extreme temperatures or with toxic substances. This minimizes human contact with danger.

However, the shift to automation isn't flawless. While machines enhance safety, they also introduce new challenges. Workers must adapt quickly to new technologies. Training is crucial, but it can be overlooked. Some employees may feel uneasy around robots, fearing job loss. Effective communication about the importance of their roles amid automation is vital.

Additionally, maintenance of automated systems is essential. Unattended machine malfunctions could pose risks. It is a reminder that technology is not infallible. Regular checks can prevent accidents and ensure a safe work environment. Thus, while automation improves safety, continuous reflection on its implementation is necessary.