In today's fast-paced world, production automation is transforming industries. This technology improves efficiency and reduces costs. It allows companies to produce goods with precision and speed. As a result, manufacturers can meet growing consumer demands more effectively.

While production automation offers many advantages, it is not without challenges. For instance, reliance on automated systems can lead to job displacements. Workers may find it hard to adapt to new skills required by automated processes. Furthermore, initial investments in automation technology can be substantial. Companies must weigh these factors carefully.

Despite these concerns, the benefits of production automation are hard to ignore. By streamlining operations, businesses can increase productivity and enhance product quality. Successful implementation requires thoughtful planning and a clear understanding of potential pitfalls. In the end, the future of modern industries may hinge on effective automation strategies.

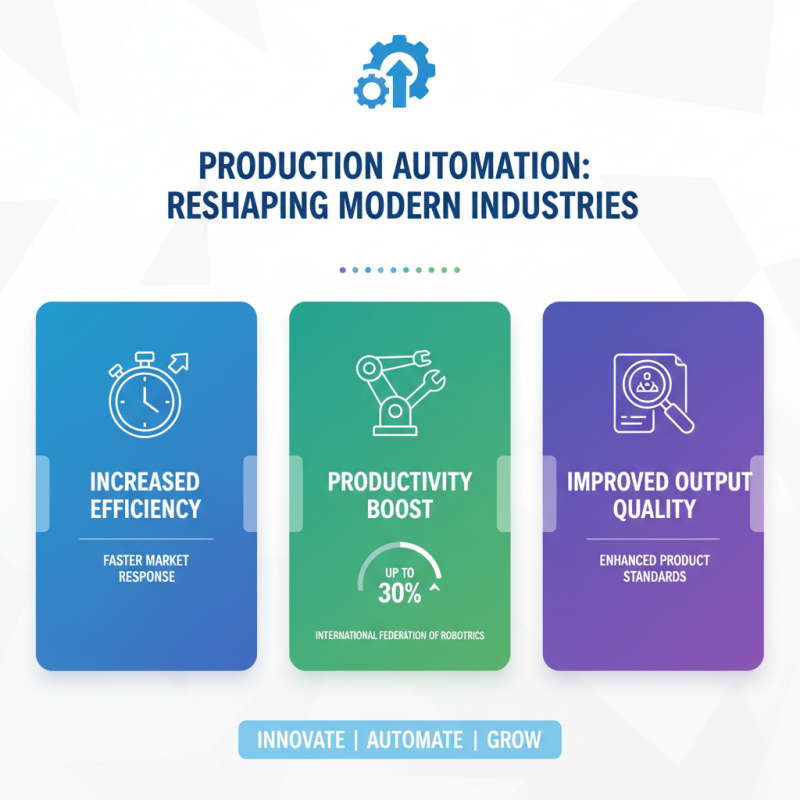

Production automation is reshaping modern industries. One of the key advantages is increased efficiency. A recent report from the International Federation of Robotics indicates that automating production can boost productivity by up to 30%. This significant rise helps companies respond faster to market demands and improve output quality.

With automation, businesses streamline operations. They reduce the number of errors and waste. For instance, a study by McKinsey & Company shows companies can save up to 20% on operating costs through automation. However, the transition isn't always seamless. Workers may feel uncertain about their roles. Employers must address these changes thoughtfully.

Improvements in efficiency also raise questions. Are we compromising job security for speed? Balancing productivity gains with employee wellbeing is crucial. The industry needs a holistic approach. Embracing automation means evaluating its broader impacts. This way, companies can truly benefit from the advancements while maintaining a committed workforce.

Automation technologies are revolutionizing modern industries by significantly cutting operational costs. Manufacturing processes that once required large teams can now be streamlined with advanced machines. These devices work continuously, reducing labor hours and human errors. For instance, a factory may see its production speed double while cutting labor costs by a substantial margin.

Implementing automation also reduces waste in several ways. Instruments can optimize raw material usage, leading to fewer discarded products. However, this shift to automation is not without challenges. Some companies face employee resistance. Workers may worry about job security, which can lead to low morale and lower productivity. Navigating this human side of automation is crucial.

Furthermore, maintenance of automated systems requires skilled personnel. Training programs can consume time and resources. Sometimes, new technologies also mean unforeseen expenses. Industries must be cautious, reflecting on their long-term strategies and ensuring support for employees during this transition. Balancing efficiency with the human touch remains vital.

Automation has become a pivotal force in modern industries, particularly in enhancing product quality and consistency. Through precision machinery and robotics, businesses can execute tasks with unrivaled accuracy. This reduction in human error can lead to fewer defects in products, ensuring higher standards during production. For example, automated quality checks can detect imperfections that may go unnoticed by the human eye.

However, relying heavily on automation raises questions. What happens when a machine malfunctions? Production halts, and the workflow is disrupted. While automation improves efficiency, companies must create contingency plans. Training staff to manage these situations is crucial. An overbearing focus on automation might also stifle creativity. Employees could feel less engaged in their work, leading to a decline in innovation.

Additionally, achieving true consistency requires constant monitoring. Machines need regular maintenance to uphold quality. Even slight variations in material can affect the final product. Companies should continuously re-evaluate their automated processes. Seeking a balance between automation and human oversight can lead to superior outcomes. Reflecting on these challenges is essential for sustained growth in the industry.

This bar chart illustrates the top benefits of production automation in modern industries, showcasing how automation enhances efficiency, product quality, cost savings, flexibility, and safety in manufacturing processes.

Production automation has become essential for modern industries. It significantly improves workplace safety. Automated systems can take on dangerous tasks, reducing the risks for workers. For example, machines can handle heavy lifting, which minimizes the chances of workplace injuries. When human workers are removed from hazardous environments, safety statistics improve dramatically.

Reducing human error is another advantage of automation. People may overlook details or make mistakes under pressure. Automated processes can consistently perform tasks with precision. However, relying solely on technology presents challenges. Systems can fail, leading to production delays or safety risks if not monitored properly. Continuous evaluation of automated systems is necessary to ensure safety and reliability.

Balancing automation with human oversight can create a safer workplace while maximizing productivity.

In modern manufacturing, scalability and flexibility are critical. Production automation significantly enhances both aspects. According to a report from McKinsey, companies implementing automation can see up to a 30% increase in production capacity. This growth allows businesses to meet rising consumer demands swiftly.

Automation can adapt processes to different production volumes with ease. For instance, when market trends shift, systems can quickly recalibrate. A study by the International Federation of Robotics found that 75% of manufacturers reported improved flexibility after adopting automation. However, not all approaches yield positive results. Some companies struggle with integrating automated systems effectively.

Workforce training remains a challenge. Employees may feel overwhelmed by rapid technological shifts. Research from PwC indicates that 40% of workers express concern about automation leading to job displacement. Businesses must ensure that they invest in retraining programs to alleviate these worries. By fostering a culture of continuous learning, companies can balance automation benefits with workforce stability.

| Benefit | Description | Impact on Scalability | Impact on Flexibility |

|---|---|---|---|

| Increased Efficiency | Automation improves production speed and reduces cycle times. | High scalability allows production levels to be easily adjusted to meet demand. | Flexible automation systems can adapt to different product variations. |

| Cost Reduction | Reduces labor costs and minimizes waste materials. | Lower costs facilitate the scaling up of operations. | Cost-effective to switch production lines or modify operations. |

| Improved Quality Control | Consistent quality through precise automation technology. | Enhanced quality supports scaling operations without quality loss. | Quick adjustments can be made to meet specific client needs. |

| Enhanced Safety | Reduces manual labor risks and improves workplace safety. | Scalable safety measures can be implemented as operations grow. | Flexible technology can be adapted to new safety protocols. |

| Data-Driven Insights | Automation systems collect and analyze production data for better decision-making. | Data insights help predict demands for scaling operations effectively. | Flexibility in production based on real-time data and market trends. |