The laser cutting machine industry is evolving rapidly. By 2026, innovations will redefine capabilities and efficiency. According to a report by Technavio, the global laser cutting machine market is expected to grow at a CAGR of 7.5% from 2021 to 2026. This growth highlights increasing adoption in manufacturing sectors.

Dr. Emily Carter, a renowned expert in laser technology, states, "The right laser cutting machine can revolutionize production lines." Her insight points to the necessity of selecting the appropriate machine based on specific needs. Many businesses overlook the importance of understanding machine specifications, leading to potential inefficiencies.

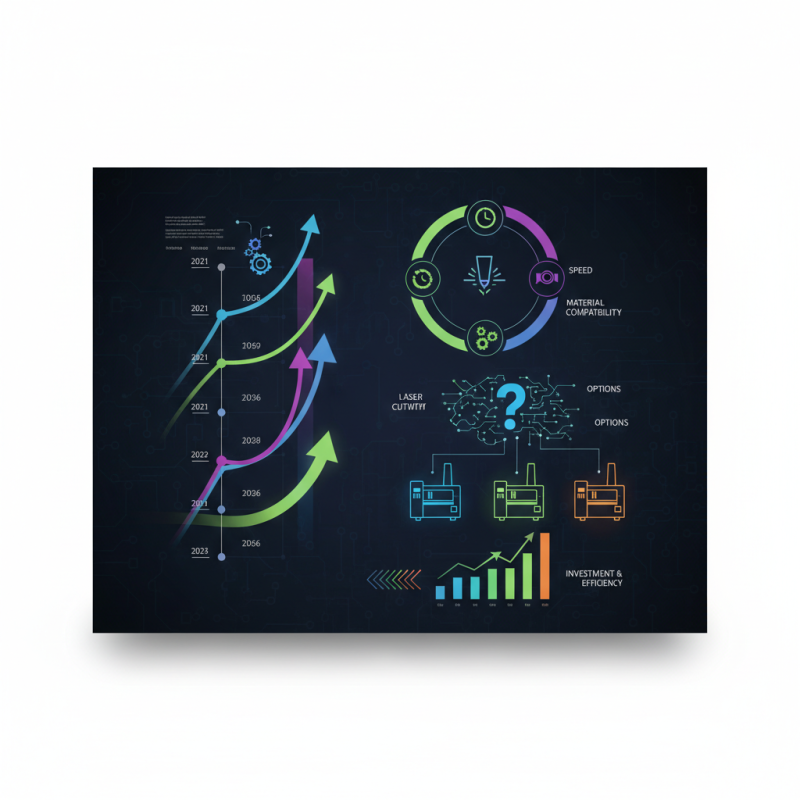

As options expand, users face tough decisions. The choice isn't simply about cost; factors like speed, precision, and material compatibility must be considered. This complexity can overwhelm newcomers. Additionally, investments in technology need careful evaluation. Time and resources are at stake. Users must reflect on their unique requirements for effective outcomes.

Laser cutting technology has evolved significantly by 2026. This technique uses focused beams of light to cut through various materials. It offers precision and versatility, making it popular in many industries. From metal to wood, the applications are vast and continually growing.

In manufacturing, laser cutting enables intricate designs and faster production times. It’s also embraced in fashion, where unique patterns are essential. Yet, challenges remain. The machines can be costly, and operational skills are vital. Many users struggle with interpreting designs accurately.

Moreover, safety and maintenance require attention to detail. With ongoing advancements, the future looks promising. However, users must remain vigilant about learning and adapting. Continuous education is necessary to maximize the potential of laser cutting technology. As applications expand, so do the possibilities for innovation and creativity in this field.

When selecting a laser cutting machine, key features are essential to consider. Precision is paramount. A machine with a cutting accuracy of ±0.01 mm can dramatically improve your results. Reports indicate that users prefer machines with higher wattage for faster cuts. The most effective models operate within the 100-200 watt range, balancing speed and quality.

Another critical feature is the cutting area. A larger work area allows for versatile designs and reduced material wastage. Machines featuring an area of at least 1200 x 800 mm tend to thrive in industrial settings. Additionally, software compatibility plays a vital role. Machines that support popular CAD programs can save time and streamline workflows.

Lastly, maintenance requirements shouldn't be overlooked. Regular upkeep is necessary for longevity. Many users express frustration with complex maintenance processes. A simpler design can ease this burden. Performance, ease of use, and cost-effectiveness should guide your decision. Each feature relates directly to your specific needs and project goals. It's essential to weigh these factors carefully.

Laser cutting technology has evolved rapidly, with CO2, fiber, and diode lasers becoming popular options. Each technology has unique strengths and weaknesses. For instance, CO2 lasers excel in cutting non-metal materials, like wood and acrylic. They are widely used in signage, crafting, and textile industries. However, their efficiency significantly drops when trying to cut metals. According to industry reports, CO2 lasers account for about 45% of the market share in the laser cutting industry.

In contrast, fiber lasers have gained traction for their high efficiency and precision, especially when dealing with metals. These lasers generate beams at a shorter wavelength, which allows for better absorption by metal materials. Reports indicate that fiber lasers can cut through stainless steel and aluminum with minimal effort. This makes them an ideal choice for automotive and aerospace applications. Yet, they can be more expensive, leading some businesses to rethink their investments.

Diode lasers represent a newer option, with increased interest in their compact and lightweight design. They are particularly effective in low-power applications and can cut thin materials with ease. However, their power limitations make them less suitable for heavy industrial use. The growth potential in the diode market is evident, but many still prioritize the traditional CO2 or fiber systems for serious cutting tasks. This illustrates an ongoing need for reflection on the best choices in laser technology.

The laser cutting industry is growing rapidly. Many manufacturers are competing for market share. Some are leaders, while others struggle to gain traction.

To choose the right laser cutting machine, consider your needs carefully. Evaluate the materials you will cut. Different machines perform better with various materials like metals, plastics, or wood. Do a little research on manufacturers. Look for ones known for quality and innovation.

When assessing manufacturers, examine their market share. A larger share often indicates customer trust and product reliability. However, smaller companies might offer unique features. They could also provide more personalized service.

Tip: Always check customer reviews and feedback. This can reveal strengths and weaknesses you might not see in marketing.

Don't forget to reflect on your long-term goals. Think about scalability. What works today might not be ideal in a few years. Always keep an eye on evolving technology in the laser cutting space.

Tip: Joining forums or groups in the industry can enhance your decision-making process. Engaging with other users offers insights you can't find elsewhere.

As we look ahead to 2026, the landscape of laser cutting machines is set to undergo significant evolution. The focus will increasingly be on enhancing performance and efficiency. Industry reports indicate that laser cutting machines will achieve an average improvement of 25% in cutting speed. Efficiency metrics will also see a 30% rise in energy savings. This shift not only reduces operational costs but also addresses growing environmental concerns.

One pivotal trend is the integration of AI for optimal cutting paths. This technology promises to improve precision and reduce material waste by up to 15%. Additionally, user interfaces will become more intuitive. However, the reliance on advanced technology may pose challenges. Not all operators will be familiar with these advancements. Training programs will be essential to bridge this knowledge gap.

Furthermore, a notable challenge remains in selecting the right machine for specific applications. With various materials and thicknesses to consider, customization will be critical. Reports show that 40% of businesses still struggle with maintenance issues due to lack of understanding. This underlines the need for ongoing support. The industry must reflect on its ability to adapt and respond to these needs effectively.

| Machine Type | Max Cutting Thickness (mm) | Speed (mm/s) | Power (W) | Material Suitability | Efficiency Rating |

|---|---|---|---|---|---|

| CO2 Laser Cutter | 20 | 300 | 150 | Wood, Acrylic | A+ |

| Fiber Laser Cutter | 25 | 400 | 500 | Metal, Plastic | A++ |

| Crystal Laser Cutter | 15 | 200 | 250 | Glass, Ceramics | A |

| UV Laser Cutter | 10 | 350 | 100 | Thin Films, Plastics | A+ |