In the rapidly evolving landscape of the manufacturing industry, automation has emerged as a key driver of efficiency and productivity. According to a report by the International Federation of Robotics, global robot sales in the manufacturing sector are projected to reach a staggering $16.5 billion by 2025, reflecting an annual growth rate of around 12%. This surge underscores the critical role that manufacturing industry automation plays in optimizing production processes and enhancing operational capabilities.

Experts in the field emphasize the importance of adopting effective automation strategies. As Dr. Amelia Chen, a leading researcher at the Robotics and Automation Institute, stated, "To thrive in a competitive market, manufacturers must harness the power of automation to streamline operations, reduce costs, and innovate products." Hearing such insights from industry leaders highlights the necessity for manufacturers to embrace a strategic approach to automation.

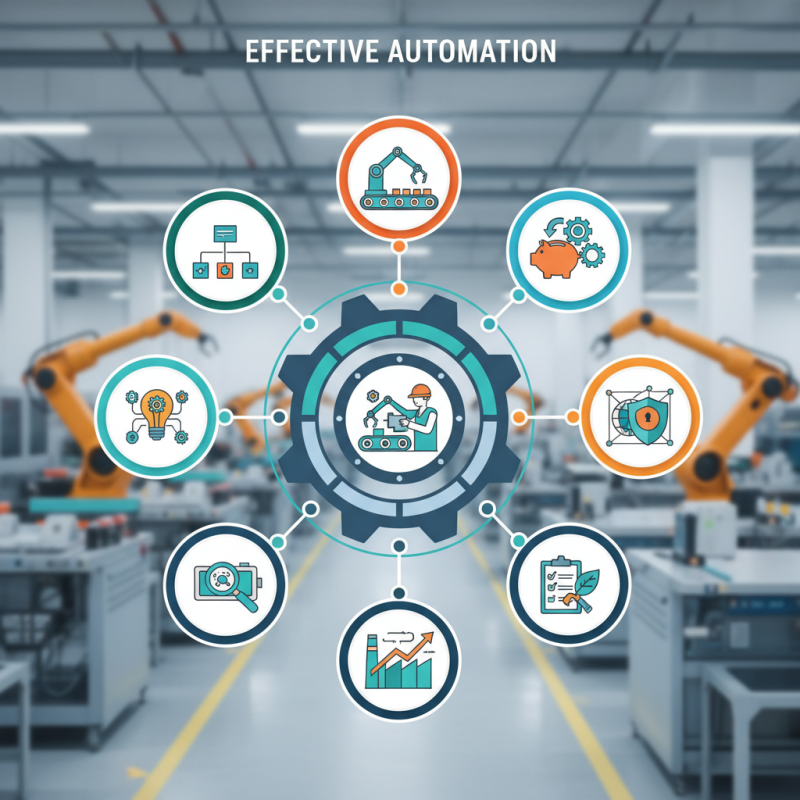

By implementing best practices and understanding the complexities of manufacturing industry automation, companies can not only improve their efficiency but also ensure they are well-prepared to meet the future challenges of the market. In the subsequent sections, we will explore the top 10 tips for achieving effective automation, providing a roadmap for manufacturers looking to elevate their operations in this dynamic environment.

Automation in the manufacturing industry has emerged as a crucial element for improving efficiency and maintaining competitiveness. According to a report by McKinsey, nearly 60% of all occupations in manufacturing have the potential to be automated, which indicates a significant opportunity for companies to enhance productivity through technology. As processes are automated, manufacturers can achieve greater precision and reduce operational costs, which leads to higher profit margins. Furthermore, a study by the International Federation of Robotics reported that global industrial robot sales have doubled from 2015 to 2020, illustrating a growing trend towards adopting automation technologies across various sectors.

Understanding the importance of automation in manufacturing goes beyond cost reduction; it also significantly impacts product quality and safety. A report by Deloitte highlighted that automated systems can reduce human error by up to 80%, which is critical in producing high-quality products consistently. Moreover, automation facilitates the implementation of advanced technologies such as IoT and AI, allowing manufacturers to monitor production processes in real time and make data-driven decisions. This shift not only streamlines operations but also enables companies to respond swiftly to market changes and customer demands, thereby enhancing their overall resilience and adaptability in an increasingly competitive landscape.

Identifying processes suitable for automation is a crucial step for any manufacturing business aiming to enhance efficiency and reduce costs. To begin, it's essential to evaluate the repetitive tasks that consume significant time and resources. Processes such as

assembly line work, quality control inspections, and inventory management often present prime candidates for automation.

By examining these routine operations, businesses can pinpoint areas where automation can lead to improved productivity and minimize human error.

Additionally, companies should consider the variability and complexity of their processes. For tasks that require precise movements or detailed measurements, automation can provide consistency and speed that manual labor might struggle to achieve. Incorporating technologies like robotics or automated guided vehicles can streamline these processes, making them not only faster but also more reliable.

It's important to incorporate a continuous feedback mechanism to analyze performance and outcomes, ensuring that the chosen processes are genuinely benefiting from automation.

Ensuring that employees are engaged in this transition is also vital. Involving them in the identification process can yield valuable insights into which tasks they find most tedious or time-consuming. By fostering an environment where feedback is encouraged, businesses can better determine the most effective automation strategies, paving the way for smoother implementation and greater acceptance of new technologies within the workforce.

When selecting the right automation technologies and tools for the manufacturing industry, it is crucial to first assess the specific needs and goals of your operations. Understanding the processes that require improvement can help in identifying the most suitable automation solutions. Factors to consider include the scale of production, the complexity of tasks, and the desired level of flexibility. A thorough analysis of these parameters ensures that the chosen technology aligns with the company's objectives and can deliver optimal efficiency.

Additionally, it's important to evaluate the compatibility of new automation tools with existing systems. Automation integration should enhance the overall workflow and not disrupt it. Look for technologies that allow for scalability, as manufacturing needs may evolve over time. Moreover, consider the ease of use and support provided by technology vendors to facilitate a smoother transition for the workforce. By carefully selecting automation technologies based on these criteria, manufacturers can pave the way for a more efficient and productive environment.

Successful automation in the manufacturing industry hinges not only on the technology itself but also on the employees who operate it. To ensure a smooth transition to automated processes, companies must invest in comprehensive training programs tailored to equip their workforce with the necessary skills. This begins with clear communication about the goals of automation and how it will enhance their roles rather than replace them.

One crucial tip for effective training is to start with foundational knowledge about the new technology. Employees should understand how automation tools function and the benefits they bring to the production line. Practical, hands-on training sessions will empower workers to familiarize themselves with the equipment, leading to increased confidence and competence. Additionally, involving employees in the decision-making process can foster a sense of ownership and commitment to the changes.

Another valuable approach is to create continuous learning opportunities that adapt as technology evolves. This could involve regular workshops, online courses, and mentorship programs that keep employees updated on best practices and emerging tools. By nurturing a culture of ongoing education, manufacturers can ensure their staff remains agile and prepared for the challenges of modern automation, ultimately leading to greater efficiency and productivity on the factory floor.

In the quest for automation in the manufacturing industry, measuring success through Key Performance Indicators (KPIs) is crucial. Effective KPIs can provide insight into the efficiency of automation initiatives, helping organizations to identify areas for improvement and drive greater productivity. According to a recent report from the International Society of Automation, companies that use KPIs to track their automation effectiveness see a 20% to 30% increase in operational performance. Key metrics such as Overall Equipment Effectiveness (OEE), cycle time, and defect rates enable manufacturers to quantify their gains from automation, ensuring that investments yield substantial returns.

To enhance automation effectiveness, it’s important to consider several best practices. First, ensure alignment between automation goals and overall business objectives, which creates a cohesive strategy for deployment. Secondly, fostering a culture of continuous improvement stands as a vital component; encouraging feedback from employees involved in the automated processes can reveal valuable insights that enhance operations. A study from Deloitte indicates that companies prioritizing employee engagement in automation projects are 50% more likely to notice successful implementations. Lastly, regular review and adaptation of KPIs will help in responding to shifting market demands, ensuring that performance measurement remains relevant and effective.

Incorporating these tips not only aids in optimizing the automation processes but also supports the overall strategy of measurement, allowing businesses to stay competitive in a rapidly evolving manufacturing landscape. By systematically addressing these factors, manufacturers can chart a course towards sustained operational excellence.