In today's fast-paced market, businesses must embrace change. Industry automation offers solutions to enhance productivity and efficiency. Renowned expert Dr. Mark Reynolds states, "Industry automation is not just an option; it's a necessity for survival." His words underline the urgency of integrating intelligent systems in various sectors.

Amid rapid technological advances, many companies still hesitate. Fear of complexity often overshadows the potential benefits of industry automation. This hesitation can lead to missed opportunities. Companies must rethink their approaches. The right automation tools can streamline operations and reduce costs.

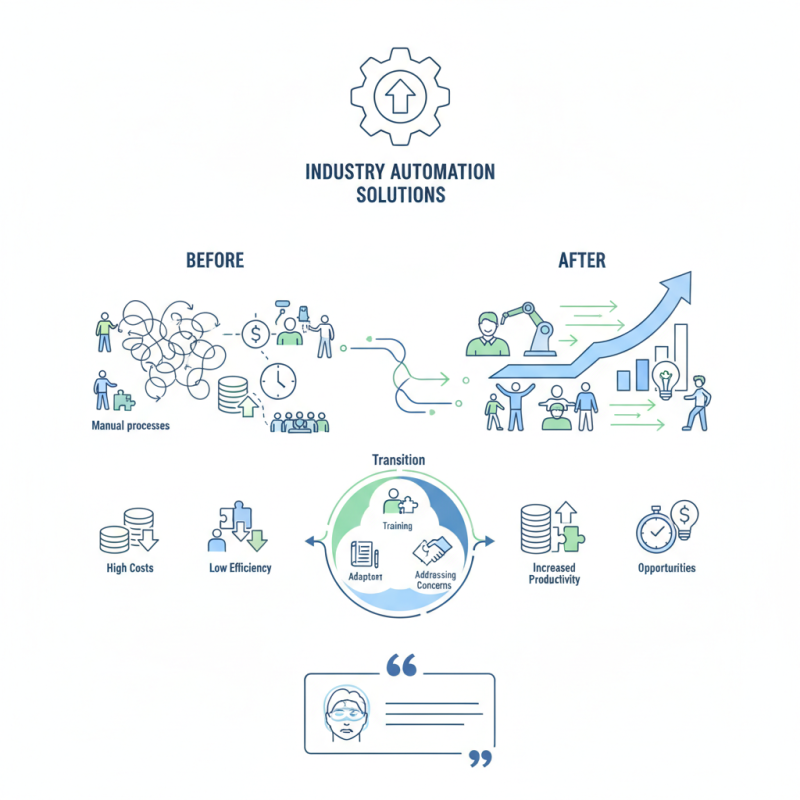

However, transitioning to automated systems isn't without challenges. Organizations may face resistance from employees. Training and adaptation require time and investment. It's crucial to address these concerns to ensure a smooth implementation. Embracing industry automation can transform a business, but careful consideration is essential for success.

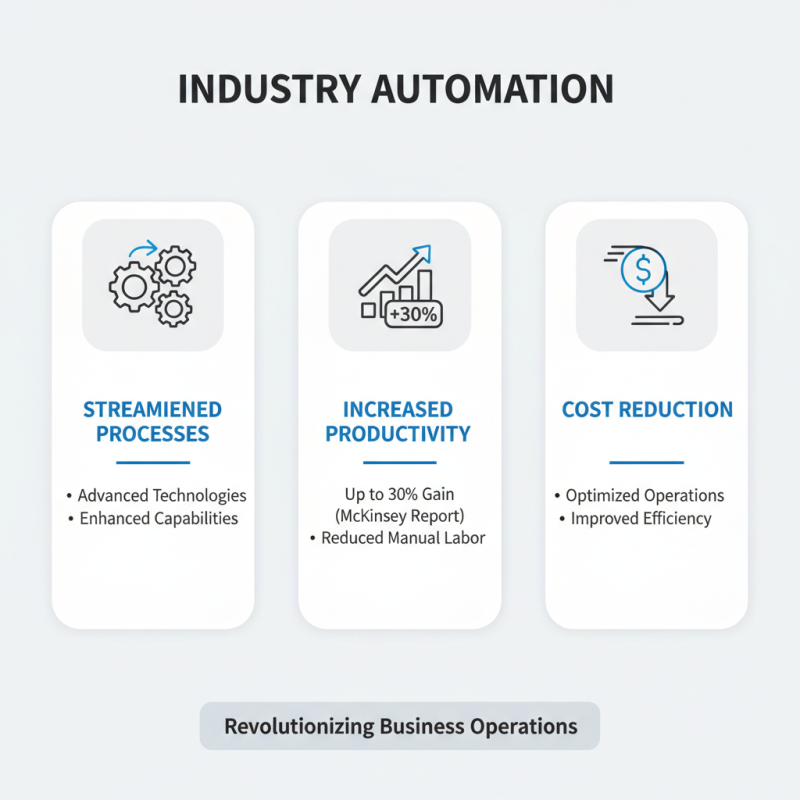

Industry automation is revolutionizing the way businesses operate. It incorporates advanced technologies to streamline processes and improve efficiency. According to a report by McKinsey, companies that implement automation can increase productivity by up to 30%. This transformation is not just about replacing human labor; it's about enhancing capabilities and reducing costs.

Understanding automation involves several key concepts. Robotics, AI, and IoT are vital components. For instance, predictive maintenance powered by IoT can save companies up to 12% in maintenance costs. However, it's not without challenges. Many businesses struggle with integration issues. The shift may require upskilling the workforce, which can create resistance.

Automation also raises interesting questions. Are we too reliant on technology? This dependence could lead to vulnerabilities. Every solution introduces new risks. Balancing efficiency and potential pitfalls is essential. As we explore automation, we need to acknowledge both its benefits and its complexities.

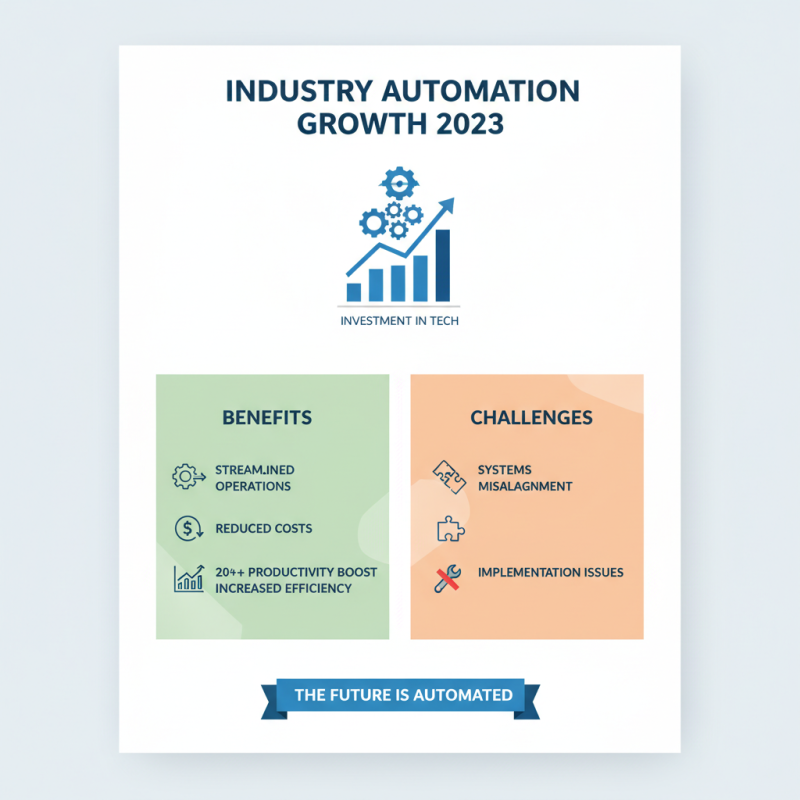

In 2023, industry automation continues to grow. Companies are investing in technology to streamline operations. Enhanced automation can lead to increased efficiency and reduced costs. Data suggests that automated processes can boost productivity by 20% or more. However, not every implementation goes perfectly. Misalignment with existing systems can cause significant issues.

Tips: Assess your current systems before diving in. A thorough evaluation can prevent future headaches. Engage your team early in the process. Their insights can help identify potential pitfalls. Remember, automation is not a one-size-fits-all solution.

Current trends mostly focus on integrating AI and machine learning. These technologies enable predictive maintenance and improve decision-making. They also open doors for better data analysis. Yet, relying solely on tech isn’t wise. Human oversight remains essential in various aspects. Developing a balance is crucial. Companies should reflect on how automation fits into their unique culture and processes.

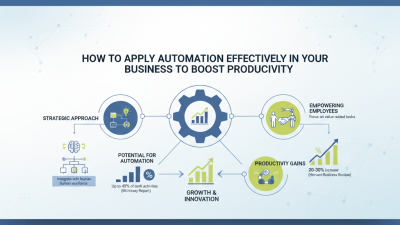

In today's fast-paced marketplace, businesses increasingly seek automation solutions to streamline their operations. These innovations are not just tools but strategic assets that can dramatically cut costs. For instance, automating repetitive tasks reduces the need for manual oversight. This can lead to fewer errors and lower operational expenses. The initial investment might seem high, but the long-term savings are often worth it.

Increased efficiency is another significant benefit. Automation allows companies to allocate resources more effectively. With machines handling mundane tasks, employees can focus on strategic initiatives. However, implementing automation is not without challenges. It requires a thoughtful approach to training staff and integrating new systems. Companies must regularly assess their processes and technology. This ensures that they yield the desired improvements. Continuous adjustments may be necessary to fully harness the power of automation.

| Automation Solution Type | Cost Reduction (%) | Increased Efficiency (%) | Implementation Time (Months) | Example Applications |

|---|---|---|---|---|

| Robotic Process Automation | 30% | 40% | 3 | Data Entry, Invoice Processing |

| Manufacturing Automation | 25% | 35% | 6 | Production Lines, Quality Control |

| Supply Chain Automation | 20% | 30% | 4 | Logistics Management, Inventory Tracking |

| Customer Service Automation | 15% | 25% | 2 | Chatbots, Helpdesk Automation |

| HR Automation | 18% | 28% | 5 | Employee Onboarding, Payroll Processing |

Implementing automation in your business can lead to significant operational efficiencies. However, achieving this success requires careful planning. One key aspect is identifying suitable processes for automation. Not all tasks are fit for automation. Some processes may have complex variables, leading to challenges. Misjudging this can waste time and resources.

Training staff is another crucial factor. Many employees may feel threatened by automation. It’s vital to communicate that automation aims to enhance their roles, not replace them. Offering comprehensive training can smooth this transition. Yet, many companies overlook this step. This can create a gap, leaving employees feeling unprepared and resistant to change.

Integrating automation solutions can present technical challenges. System compatibility issues often arise. It may require significant IT resources to resolve these problems. Businesses should have a backup plan to address potential failures. Recognizing these challenges early can lead to better outcomes. Embracing continuous feedback is essential. It helps in refining the automation process and aligning it with business goals.

This bar chart illustrates the significant improvement in operational efficiency before and after implementing automation solutions in businesses. As shown, automation led to a remarkable increase in productivity, highlighting its importance in modern business practices.

Automation has transformed various industries, showcasing significant benefits through case studies. In manufacturing, for instance, companies implementing automation report productivity increases of up to 30%. A study by the International Federation of Robotics indicates that automation capabilities can reduce labor costs by 30% over five years. However, not all automation strategies yield the same results. Some businesses struggle with integrating new technologies effectively.

In the healthcare sector, automation has streamlined processes, significantly improving patient care. A report by the Healthcare Information and Management Systems Society reveals that automation can cut administrative costs by nearly 20%. Yet, the transition can face challenges. Many organizations encounter resistance from staff who fear job displacement. It’s crucial to address these concerns for successful implementation.

Retail also illustrates the impact of automation. Automated inventory systems can decrease stock discrepancies by 40%, according to a survey from a leading logistics firm. Still, some retailers find it hard to analyze data effectively. The insights gleaned can be overwhelming without proper training. Automation brings promise but requires a thoughtful approach.