In the rapidly evolving landscape of industrial manufacturing automation, achieving greater efficiency is paramount. Industry expert Dr. Lisa Chen states, "Automation should never be a set-and-forget strategy." This highlights the need for continuous evaluation and enhancement of automation processes.

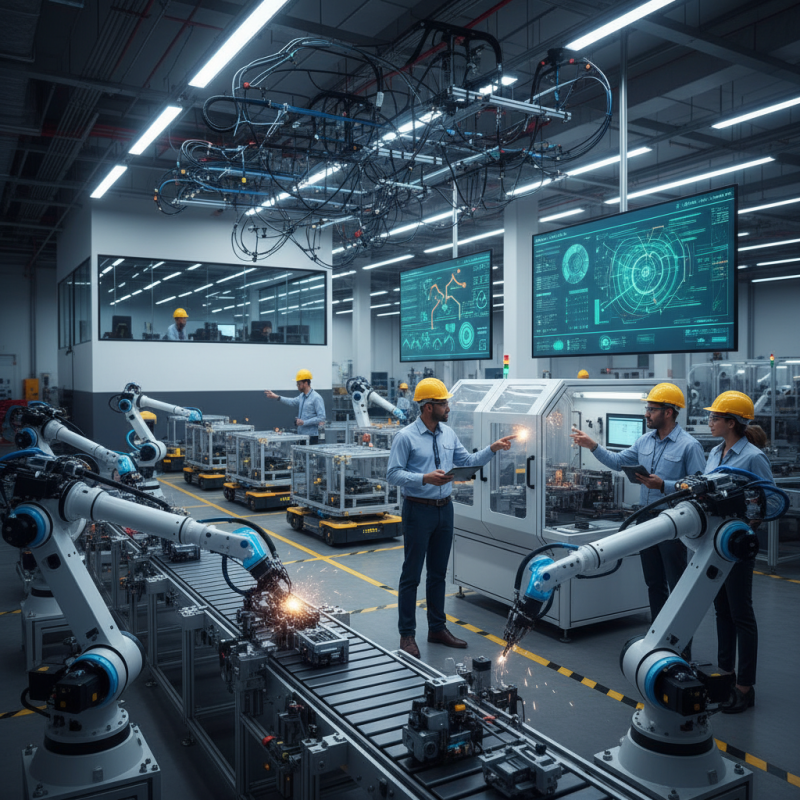

Integrating advanced technologies can transform production floors. Robotics, AI, and IoT are driving significant changes. However, not every implementation yields immediate benefits. Sometimes, companies face unexpected challenges that require further adjustments. Identifying these issues is crucial for long-term success.

Furthermore, fostering a culture of innovation can lead to breakthroughs. Employees should feel empowered to suggest improvements. Yet, not all ideas will be effective. Testing and refining concepts is essential. This iterative process ultimately strengthens the foundation of industrial manufacturing automation. It's about progress, not perfection.

The Industrial Internet of Things (IIoT) is a game-changer for manufacturing. Reports indicate that by 2025, the global IIoT market is expected to reach $110 billion. This growth presents opportunities for manufacturers to enhance automation and efficiency. Implementing IoT can improve real-time monitoring. It helps gather data that reveals inefficiencies in production lines.

Many businesses face challenges while adopting IIoT. Integration with existing systems can be complex. Data silos often obstruct smooth communication between devices. Yet, overcoming these obstacles can lead to remarkable improvements. For example, predictive maintenance can cut downtime by up to 50%. This strategy helps foresee equipment failures and reduces unexpected repairs.

Safety is another area where IoT shines. Connected devices can monitor environmental conditions and alert staff to potential hazards. In this regard, it’s crucial to prioritize cybersecurity. Weaknesses in security can lead to costly breaches. Reports suggest that 60% of small to medium-sized manufacturers lack robust cybersecurity measures. As companies pursue IIoT integration, they must address these vulnerabilities seriously.

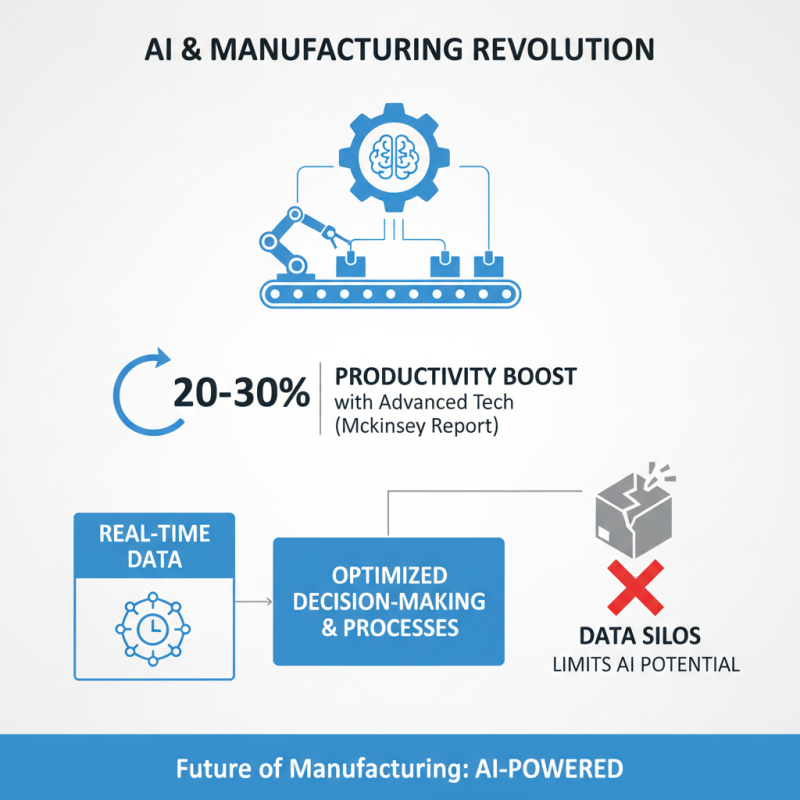

In recent years, the manufacturing sector has seen a shift toward automation powered by AI and machine learning technologies. According to a report by McKinsey, firms that integrate advanced technologies can enhance productivity by up to 20-30%. This becomes particularly critical in environments where real-time data can drive decision-making and manufacturing processes. Yet, many factories struggle with data silos, limiting their ability to leverage this powerful information.

Implementing AI solutions can optimize production by predicting machine failures and scheduling maintenance. For example, predictive analytics can reduce downtime significantly. However, the challenge remains in the initial integration of AI systems. Many companies report difficulties in adapting their legacy systems to new technologies. A study from PwC indicates that nearly 75% of manufacturers say their existing data infrastructure is not ready for AI. This is a clear gap that needs addressing for successful optimization.

By collecting and analyzing real-time production data, manufacturers can enhance efficiency. Real data can reveal discrepancies in the production line that traditional methods may overlook. Yet, a substantial percentage of companies fail to act on data insights effectively. Companies may invest in AI but still overlook the need for comprehensive training programs for their workforce. This oversight can hinder the overall effectiveness of the technology and impact the expected return on investment. The journey towards fully automated manufacturing continues to pose challenges and learning opportunities.

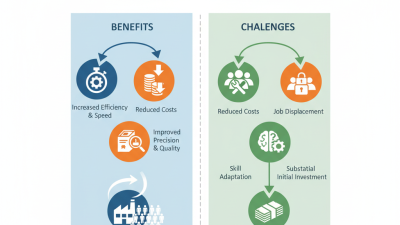

In the realm of industrial manufacturing, integrating robotics significantly boosts productivity and reduces operational costs. Recent reports show that companies implementing automation can see efficiency gains of up to 30%. Robots handle repetitive tasks swiftly, minimizing human error and increasing output. This efficiency directly correlates with time saved in production cycles.

However, the transition to robotic automation is not without challenges. A survey found that nearly 70% of manufacturers face difficulties in integrating new technologies with existing systems. This gap can lead to temporary declines in productivity. Training staff to work alongside robots is also crucial. Investing in workforce education helps maximize the benefits of automation.

Data continues to illustrate that operational costs decrease by as much as 20% when robotics are embraced. Yet, the initial investment remains a barrier for many. Balancing cost and productivity is an ongoing conversation. It is essential to reflect on these factors while pursuing automation in manufacturing.

| Automation Technology | Impact on Efficiency (%) | Reduction in Operational Costs (%) | Implementation Time (months) | Return on Investment (ROI) (%) |

|---|---|---|---|---|

| Robotic Process Automation (RPA) | 30 | 20 | 6 | 150 |

| Automated Guided Vehicles (AGV) | 25 | 15 | 8 | 120 |

| Collaborative Robots (Cobots) | 35 | 25 | 5 | 170 |

| Machine Learning Algorithms | 40 | 30 | 9 | 200 |

| IoT Integration | 28 | 18 | 7 | 140 |

In today's industrial landscape, data analytics plays a vital role in enhancing automation efficiency. Monitoring key performance indicators (KPIs) allows manufacturers to identify bottlenecks quickly. For instance, a report by McKinsey indicates that organizations using advanced analytics can improve productivity by up to 20%. This is a clear signal that leveraging data can lead to significant gains.

Implementing real-time monitoring systems is crucial. These systems provide instant feedback on machinery performance, helping teams to make informed decisions. Reports show that 70% of companies face challenges in data integration across platforms. This fragmentation can hinder effective analyses and slow down response times. Thus, addressing this issue is imperative for continuous improvement.

However, not all data leads to actionable insights. Companies often collect vast amounts of information but fail to interpret it effectively. A Gartner study highlighted that 88% of data collected is never analyzed. This underutilization can create inefficiencies rather than fostering innovation. A culture of reflection on data usage is necessary to bridge this gap.

In today's rapidly evolving industrial landscape, enhancing workforce training is crucial. Automation is not just about machines; it's also about people. When employees understand automated systems, they can work more effectively. This requires customized training programs that cater to different skill levels. For instance, newer employees may need more hands-on guidance, while experienced staff may benefit from advanced workshops.

Collaboration plays a key role in an automated environment. Teams should regularly meet to discuss challenges and share knowledge. An open line of communication fosters a culture of learning. It’s not uncommon for some employees to feel disconnected or overwhelmed by technology. Addressing these concerns openly can help build trust and enhance team dynamics. Creating scenarios where employees can practice troubleshooting in groups can bridge this gap.

Real-world applications of training programs can highlight their importance. Simulated environments can be set up for practice, enabling workers to experience situations they may face. However, ensuring that all personnel engage fully can be challenging. Some employees may resist change, feeling uncertain about technology’s role in their jobs. This resistance must be acknowledged and addressed to maximize automation benefits.