Manufacturing automation is transforming the production landscape. According to a report from McKinsey, automated processes could reduce operational costs by up to 30%. This shift is not just about robotics; it includes data integration and predictive analytics. Businesses that embrace this change stand to gain a competitive edge.

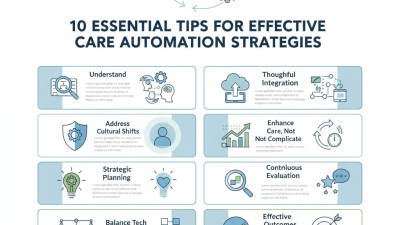

However, implementing manufacturing automation comes with challenges. Many companies struggle to align technology with their current workflows. A study by Deloitte shows that 54% of manufacturers find it difficult to adapt. This gap can hinder potential benefits. A well-thought-out strategy is essential for success.

A gradual approach to automation may yield better results. For instance, pilot projects can provide insights before full-scale implementation. Reflecting on these experiences is crucial. The journey to effective manufacturing automation requires continuous learning and adaptation. Each step taken will shape the future of production in your business.

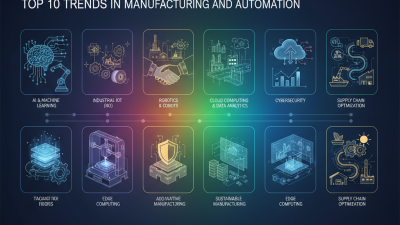

Manufacturing automation is transforming industries globally. Understanding its basics is crucial for businesses. According to a report by McKinsey, automation can boost productivity by 20-25%. This presents both an opportunity and a challenge. Companies must not only invest in technology but also in training their workforce.

The first step in automation is identifying repetitive tasks. These can include assembly line operations, quality checks, and material handling. A study from the World Economic Forum noted that 75 million jobs may be displaced due to automation by 2025. However, it also predicts that 133 million new roles could emerge, requiring different skills. This highlights the need for companies to reconsider their workforce strategies.

Deploying automation is not just about machines. It's about integrating technology with human skills. Businesses may face resistance from employees fearing job loss. Open communication is vital. To build trust, companies should involve their workforce in the transition process. This can lead to creative solutions and a more engaged team. Understanding the basics of manufacturing automation is a step forward, but practical implementation requires careful thought.

Identifying key areas for automation in your business is crucial. Start by analyzing repetitive tasks. These often consume significant time. For example, inventory management takes hours each week. Automating this can save resources. Look into software solutions that handle tracking and ordering.

Next, consider production processes. Manual assembly lines can be slow. Introducing robotic systems can increase efficiency. However, evaluate the investment carefully. The upfront costs may be high. Yet, the long-term benefits often justify the expense.

Don’t overlook customer service. Automation here can enhance response times. Chatbots can handle inquiries efficiently. Nevertheless, they may not replace personal touch entirely. Customers often appreciate human interaction at crucial points. Striking a balance is key. Regularly review automated processes for improvements and effectiveness.

Evaluating technology options for manufacturing automation is crucial. Begin by assessing your current processes. Identify areas that require improvement. Look for repetitive tasks that can benefit from automation. Data collection is essential. Analyze production metrics to highlight bottlenecks. Understand your specific needs before investing.

Explore various automation technologies. Robotics, for example, can enhance precision and speed. However, consider the maintenance costs and the learning curve for your staff. Don't overlook software solutions. These can integrate with existing systems and streamline operations. Remember, sometimes less is more. Over-automating may lead to complications.

Each technology comes with its pros and cons. It's vital to run trials before full implementation. Gauge employee feedback. Their insights can help refine your approach. Document any issues encountered during automation. Continuous evaluation and adjustment are necessary. Always question if the technology meets the desired objectives efficiently.

| Technology Option | Description | Benefits | Challenges | Estimated Cost ($) |

|---|---|---|---|---|

| Robotic Process Automation | Utilizing robots to perform repetitive tasks | Increased efficiency and reduced human error | High initial investment and training requirements | 50,000 - 200,000 |

| Industrial IoT | Connecting machines and sensors to the internet | Real-time data collection and predictive maintenance | Security concerns and network reliability | 30,000 - 150,000 |

| Computer Numerical Control (CNC) Machines | Automated control of machining tools via computer | High precision and repeatability in manufacturing | Requires skilled personnel for programming and maintenance | 20,000 - 100,000 |

| Automated Inventory Management | Using software and sensors to manage inventory | Reduces stockouts and overstock situations | Integration with existing systems can be complex | 10,000 - 50,000 |

Implementing manufacturing automation requires a well-structured plan. Start by assessing your current processes. Identify areas that need improvement. Consider what tasks can be automated effectively. This analysis sets the stage for a smooth transition.

Tip: Involve your team early. Gather input from employees on what works and what doesn’t. Their insights can help pinpoint potential issues. Communication is key throughout this change. Address concerns and encourage feedback.

Next, outline a step-by-step implementation plan. Break down the automation process into manageable chunks. Set realistic deadlines for each phase. Tackle one area at a time to avoid overwhelming the system. Monitor progress closely. This helps you adapt if something doesn't go as expected.

Tip: Train your staff on new technologies. They need to be comfortable with any automated systems. Continuous learning keeps everyone engaged. Evaluate performance regularly, too. Reflect on what’s working and what needs improvement. Automation is not a one-time fix; it’s an ongoing journey.

This chart illustrates the estimated hours spent on each phase of implementing manufacturing automation in your business. Effective planning is crucial for successful integration and scaling.

Measuring the success of manufacturing automation is critical. A recent industry report notes that 90% of companies struggle with quantifying the benefits of automation. Many businesses focus on tech implementation without proper metrics. This oversight can lead to missed opportunities for optimization.

To effectively measure automation success, define clear KPIs. Key Performance Indicators should align with business goals. Consider metrics like production speed, error rates, and labor costs. This data reveals areas for improvement. A study found that manufacturers with well-defined KPIs see a 30% increase in productivity. Collecting regular feedback from employees helps refine processes, too.

Tip: Regular check-ins with your team can highlight automation pitfalls. They often see issues you may overlook. Another suggestion is to invest in training. Ensure staff can adapt to new systems smoothly. Remember, measurement is an ongoing process, not a one-time event. Reflecting on your strategy will help you stay agile in a changing market.