As the landscape of manufacturing continues to evolve, the year 2023 has marked significant advancements in manufacturing automation, redefining the way industries operate. According to Dr. Jane Smith, an expert in manufacturing technologies, "The future of manufacturing automation is not just about increasing efficiency, but also about enhancing adaptability and resilience in production processes." This insightful perspective encapsulates the pressing need for manufacturers to embrace innovative automation trends that address both current challenges and future demands.

In an era where digital transformation drives growth, the integration of advanced technologies such as AI, IoT, and robotics has reshaped traditional manufacturing environments. As organizations seek to optimize production capabilities, the investment in manufacturing automation has become paramount. By automating repetitive and time-consuming tasks, companies can improve productivity, reduce costs, and ensure higher-quality outputs.

Furthermore, as we delve into the top 10 manufacturing automation trends shaping the industry this year, it is crucial to understand how these developments not only streamline operations but also foster greater sustainability and workforce empowerment. Embracing these trends will be vital for manufacturers aiming to stay competitive and resilient in an increasingly complex marketplace.

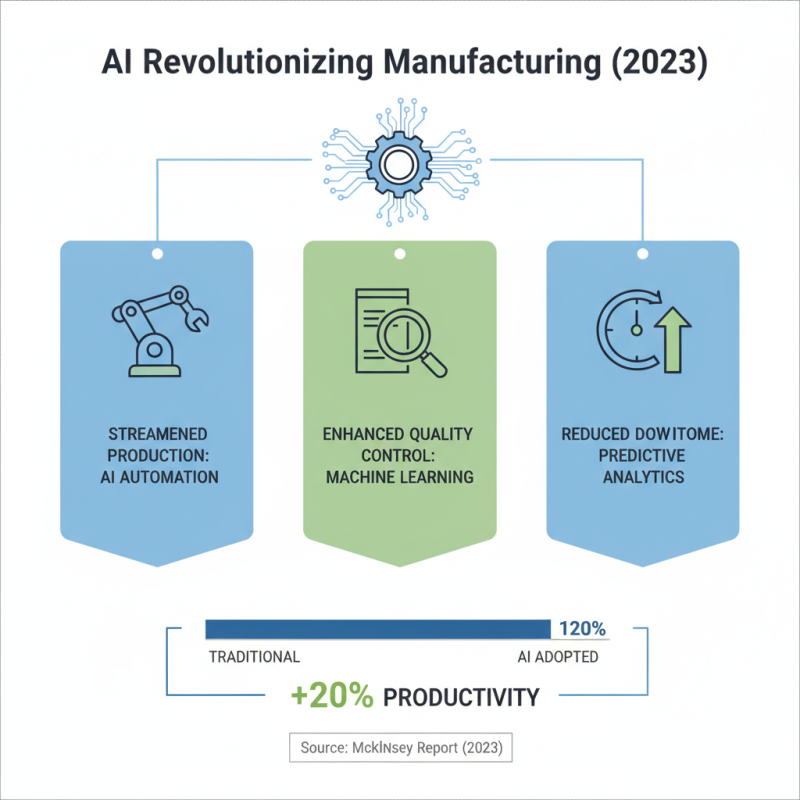

The manufacturing industry is undergoing a significant transformation in 2023, largely driven by the emergence of artificial intelligence (AI) in automation processes. AI technologies, including machine learning and predictive analytics, are reshaping operational efficiencies by streamlining production lines, enhancing quality control, and reducing downtime. According to a recent report by McKinsey, organizations that aggressively adopt AI in their manufacturing processes have witnessed productivity increases of up to 20%, demonstrating the clear impact of these innovations.

One of the most exciting developments is the use of AI-driven robots that can adapt to changing production needs in real-time. This flexibility not only allows manufacturers to respond quickly to market demands but also optimizes the allocation of resources. A survey by Deloitte indicates that 82% of manufacturing executives plan to increase their AI investments to improve operational workflows and drive cost savings. This is an illustration of how AI is no longer just a theoretical concept but an integral part of modern manufacturing strategy.

Tips: For manufacturers looking to leverage AI, it is crucial to start with data management. Ensuring high-quality data collection and storage systems will set a strong foundation for AI initiatives. Additionally, investing in employee reskilling will maximize the benefits of automation technologies. Engaging workers in the transition can foster a culture of innovation, which is essential for successful adaptation in this rapidly evolving landscape.

The integration of the Internet of Things (IoT) is revolutionizing manufacturing automation, enhancing operational efficiency and productivity across the industry. As reported by a recent study from McKinsey, the utilization of IoT technologies can lead to efficiency improvements of up to 25% in manufacturing processes. IoT facilitates real-time data collection and analysis, enabling manufacturers to monitor equipment performance, predict maintenance needs, and optimize resource allocation. For example, sensor-equipped machinery can relay operational data instantaneously, allowing for immediate adjustments that minimize downtime and reduce waste.

Furthermore, the implementation of IoT solutions is transforming supply chain dynamics. According to a report by Gartner, over 50% of manufacturers are expected to adopt IoT in their supply chain management by the end of 2023. This integration not only streamlines inventory management but also enhances visibility throughout the supply chain. By employing IoT devices, companies can gain deeper insights into inventory levels, demand forecasting, and logistics operations, leading to more agile and responsive production environments. As manufacturing continues to embrace these technological advancements, the IoT is becoming a cornerstone of operational strategy, driving competitiveness and fostering innovation in the sector.

Robotic Process Automation (RPA) is at the forefront of transforming production lines in the manufacturing sector. By seamlessly integrating software robots into operational workflows, RPA minimizes human intervention in repetitive tasks, enhancing efficiency and accuracy. This shift not only reduces the likelihood of errors but also allows human workers to focus on more complex and strategic activities, thus elevating overall productivity. As companies increasingly adopt RPA technologies, the flexibility and scalability of production systems are significantly enhanced, enabling quicker responses to market demands.

Moreover, RPA's implementation in production lines facilitates real-time data analysis and decision-making. Automated systems can monitor production metrics continuously, allowing for immediate adjustments that optimize processes and reduce waste. This capability is crucial in today’s fast-paced manufacturing environment, where agility can provide a competitive edge. Additionally, as industries look towards smart manufacturing, RPA acts as a vital component in forming interconnected, intelligent systems that promote innovation and sustainability. The evolution of production lines through RPA not only drives operational excellence but also paves the way for a more responsive and adaptive manufacturing landscape.

| Trend | Description | Impact on Industry | Projected Growth (%) |

|---|---|---|---|

| Robotic Process Automation (RPA) | Automation of business processes using software robots. | Increased efficiency and reduced operational costs. | 25% |

| Artificial Intelligence | Integration of AI to enhance decision-making capabilities. | Improved accuracy and predictive maintenance. | 30% |

| Internet of Things (IoT) | Network of connected devices for real-time data collection. | Enhanced monitoring and operational insights. | 28% |

| 5G Technology | Higher bandwidth and lower latency for industrial applications. | Enables real-time communication and automation. | 20% |

| Digital Twins | Virtual models of physical assets for simulation and analysis. | Improved design and operational efficiency. | 22% |

| Cloud Computing | Access to scalable resources and data storage via the internet. | Enhanced collaboration and data accessibility. | 26% |

| Augmented Reality (AR) | Overlaying digital information onto the physical world. | Improved training and maintenance processes. | 18% |

| Sustainability Practices | Incorporating eco-friendly practices in manufacturing. | Reduction of waste and energy consumption. | 15% |

| Cybersecurity Measures | Protecting manufacturing systems from cyber threats. | Enhanced safety and network reliability. | 17% |

| Collaborative Robots (Cobots) | Robots designed to work alongside humans in the workplace. | Improved safety and productivity. | 23% |

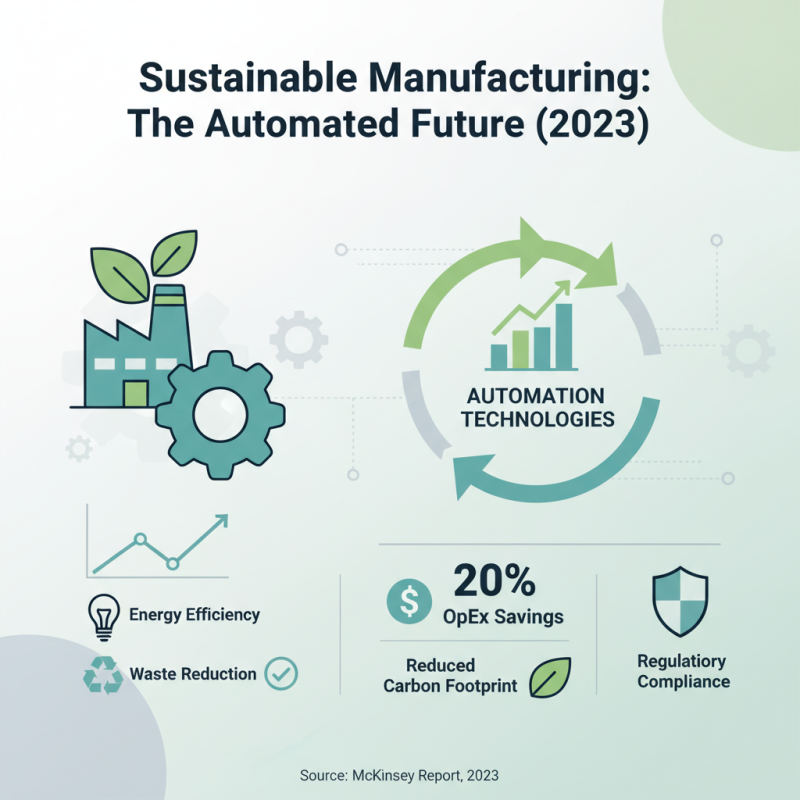

As the manufacturing industry evolves, sustainable practices driven by automation are becoming increasingly pivotal. In 2023, the integration of automation technologies in manufacturing is expected to enhance energy efficiency and reduce waste. According to a recent report by McKinsey, automating processes can save manufacturers up to 20% on operational costs and significantly diminish their carbon footprint. Companies adopting these sustainable automation practices are not only responding to regulatory pressures but also improving their overall productivity and profitability.

To maximize the benefits of sustainable manufacturing, here are some tips:

1. **Invest in Energy-Efficient Technologies**: Utilize smart sensors and IoT devices to monitor energy consumption in real-time, enabling quicker adjustments to reduce waste.

2. **Implement Predictive Maintenance**: Use automation to predict equipment failures before they occur, thus minimizing downtime and conserving resources.

Furthermore, leveraging data analytics can help manufacturers identify patterns in waste production and implement strategies to mitigate environmental impact. The International Energy Agency (IEA) forecasts that automating supply chains can lead to a 30% reduction in emissions by 2030. By embracing these automation trends, manufacturers can pave the way for a more sustainable future, ensuring their operations benefit both the environment and their bottom line.

The introduction of 5G technology is revolutionizing industrial automation systems by providing unprecedented speed, reliability, and connectivity. With its low latency and high bandwidth, 5G enables real-time data exchange between machines and centralized control systems, facilitating smoother operations on the factory floor. This capability is crucial for implementing advanced automation techniques, such as Internet of Things (IoT) devices and predictive maintenance systems, which rely heavily on constant data streaming for optimal performance.

Tips for integrating 5G into your industrial processes include starting with a thorough assessment of your current automation needs. Identify areas where real-time data communication could enhance efficiency or reduce downtime. Additionally, collaborating with technology partners who understand the complexities of 5G deployment in manufacturing can streamline the transition. As you explore 5G solutions, consider the potential for creating a more agile and responsive supply chain that can adapt to fluctuating market demands.

Moreover, investing in employee training is essential to maximize the benefits of 5G-enhanced automation. Ensuring that your workforce understands new technologies and operational frameworks will facilitate smoother implementation and greater productivity. Always keep an eye on the evolving landscape of industrial automation and stay informed about how 5G can be leveraged to gain a competitive edge in a rapidly changing market.