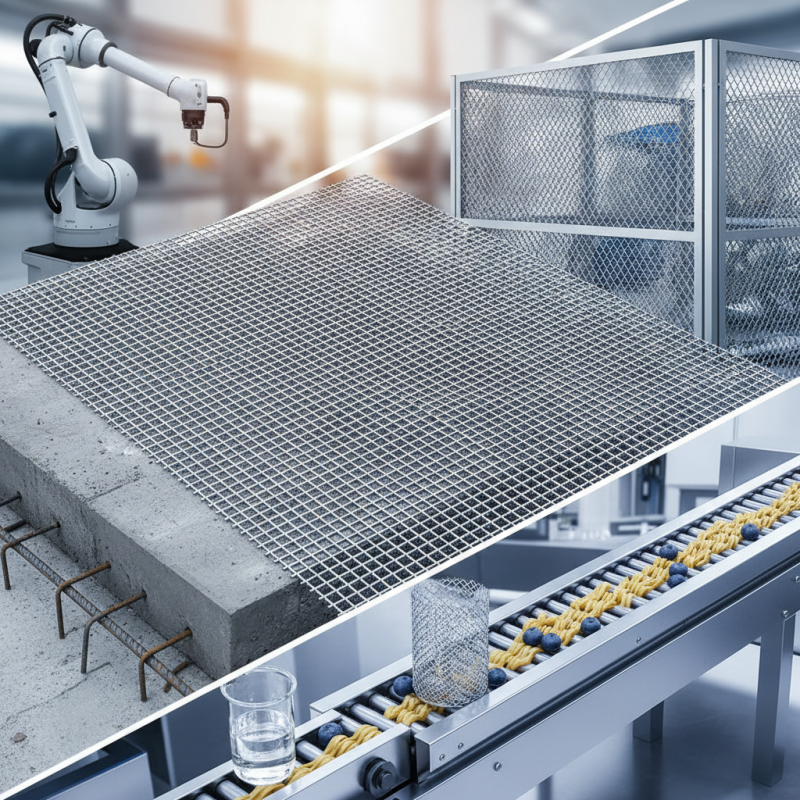

The use of stainless steel wire mesh has revolutionized various industries. Experts agree on its versatility and functionality. John Smith, a renowned metallurgical engineer, once stated, "Stainless steel wire mesh is unmatched in its ability to combine strength with flexibility." This sentiment reflects its importance in applications from construction to food processing.

In the construction industry, stainless steel wire mesh provides strength and durability. It helps reinforce concrete and supports various structural applications. In the food industry, its corrosion resistance is vital for hygiene. Stainless steel wire mesh maintains purity and safety in food production. However, many overlook its potential in filtration systems and protective barriers.

Despite its numerous benefits, stainless steel wire mesh poses challenges. The initial cost can be high. Some industries may hesitate to invest in it, considering alternatives. Yet, those who embrace stainless steel wire mesh often find it pays off over time. This material's longevity and ease of maintenance make it a worthy investment. The diverse applications are a testament to its adaptability in modern industry demands.

Stainless steel wire mesh has become a vital component in construction and architecture. Its strength and durability make it ideal for various applications. According to a recent industry report, the global market for stainless steel mesh is expected to grow by 7% annually, highlighting its increasing demand.

In buildings, this mesh is often used for reinforcement. It provides structural support while allowing for air circulation. Architects appreciate its versatility. Stainless steel mesh can be molded into various shapes and sizes. This adaptability leads to innovative designs. However, challenges exist. The mesh must be correctly installed. If not, it may compromise the overall integrity of the structure.

Moreover, stainless steel wire mesh is often employed in facades. It enhances aesthetic appeal while providing safety. Its resistance to corrosion ensures longevity. Still, some projects overlook its maintenance needs. Without regular checks, the mesh can lose its effectiveness. Ensuring proper upkeep is essential for performance. Overall, stainless steel wire mesh plays a crucial role in modern architecture, but attention to detail is vital for its optimal use.

Stainless steel wire mesh is making waves in the food processing sector. Its strength and durability give it a unique advantage. This material resists corrosion, making it ideal for various applications. For instance, many food manufacturers use it in filtering processes. It ensures that contaminants are removed, maintaining product purity. However, not all meshes perform equally well. Some manufacturers may overlook the quality of the mesh, leading to potential issues.

In packaging, stainless steel wire mesh is gaining traction. Many companies use it for creating breathable packages. These allow products to stay fresh longer while reducing spoilage. It's an innovative solution, but adjustments are often needed to optimize performance. Some might find that the mesh is too thick, affecting airflow. Smaller businesses may struggle to invest in the best options. This can create inconsistencies in product quality.

The use of stainless steel wire mesh in food processing and packaging is innovative yet nuanced. As companies explore its potential, they must also remain vigilant. Quality control in sourcing materials can be challenging. Ensuring that the wire mesh meets specific standards is crucial for food safety.

Stainless steel wire mesh is crucial in filtration and separation processes across industries. Its durability and versatility make it a preferred choice for many applications. According to recent industry reports, stainless steel wire mesh can reduce operational downtime by 30% in filtration systems. This is significant, especially in industries where efficiency is key.

In water treatment facilities, stainless steel wire mesh plays a vital role in removing contaminants. The mesh's fine weave captures particles as small as 10 microns, ensuring high-quality water output. This can lead to a 20% reduction in maintenance costs. The resilience of stainless steel also means it can withstand harsh chemicals. Manufacturers often prefer it for its ability to maintain performance over time.

However, not all stainless steel wire meshes are created equal. Some may corrode under specific conditions, leading to potential failures. It's essential to select the right grade for the intended application. Regular inspections are necessary to prevent unexpected downtime. Understanding the specific environment can help in choosing the appropriate mesh type for filtration systems.

In aerospace and automotive engineering, stainless steel wire mesh plays a crucial role. It is valued for its strength and resistance to corrosion. The aerospace industry employs stainless steel wire mesh in various applications, such as filtration and structural components. According to industry reports, the demand for lightweight materials in aircraft design is increasing. Stainless steel mesh can significantly reduce weight while maintaining structural integrity.

In automotive engineering, stainless steel wire mesh is often used in exhaust systems and air filters. Its durability helps improve vehicle performance. Reports indicate that over 30% of modern vehicles utilize such materials to enhance efficiency and reduce emissions. That makes stainless steel mesh a vital component in meeting growing environmental standards.

Tip: When selecting stainless steel wire mesh for engineering applications, consider the mesh size and wire diameter to ensure optimal performance.

Achieving the right balance can be tricky. Engineers sometimes face challenges in choosing suitable materials for complex designs. Testing different types of mesh can lead to insights that improve performance.

Tip: Always evaluate stainless steel properties like tensile strength and corrosion resistance against the specific requirements of your project.

The use of stainless steel wire mesh has significant environmental implications. Its durability and corrosion resistance make it a sustainable choice for various applications. According to industry reports, stainless steel wire mesh can last over 50 years. This longevity reduces the frequency of replacements, thereby minimizing waste.

However, producing stainless steel involves considerable energy consumption. The extraction and processing of raw materials can release harmful emissions. Some estimates suggest that the production of stainless steel emits approximately 1.8 tons of CO2 for every ton produced. This highlights a need for more eco-friendly practices in manufacturing processes. Recycling stainless steel is one solution. Over 60% of stainless steel used today is recycled. By reusing materials, industries can significantly reduce their carbon footprint.

Additionally, stainless steel wire mesh is highly efficient in filtration applications. Its ability to filter particles down to 0.5 microns ensures clean water supply and air quality. This efficiency showcases sustainability in industries like food processing and water treatment. However, not all filtration systems use this material, and exploring alternatives could lead to improved environmental outcomes. Emphasizing innovation and creativity in the environmental sector remains crucial.

| Industry | Use Case | Environmental Impact | Sustainability Benefits |

|---|---|---|---|

| Food and Beverage | Filtration of liquids and solids | Reduces waste and ensures product safety | Recyclable and long-lasting material |

| Construction | Reinforcement in concrete | Minimizes resource usage with durable material | Lifespan extends building durability |

| Automotive | Catalytic converters | Reduces emissions and increases efficiency | Enhances recycling potential of vehicles |

| Energy | Mesh for filtration in solar panels | Supports energy generation with less waste | Durability increases life cycle of panels |

| Mining | Separation of materials | Efficient resource extraction minimizes impact | Reusable material reduces landfill waste |