In an era marked by rapid technological advancements, the manufacturing and automation sectors are undergoing transformative changes that will significantly shape their future. As industries strive for efficiency, sustainability, and competitiveness, several trends are emerging that redefine traditional practices. The integration of cutting-edge technologies such as artificial intelligence, the Internet of Things (IoT), and robotics is not just enhancing production capabilities but also optimizing supply chains and improving operational workflows.

These trends are pushing the boundaries of what is possible in manufacturing and automation, fostering a new wave of innovation that prioritizes flexibility and responsiveness to market demands. As businesses navigate the complexities of digital transformation, understanding these key developments is crucial for staying ahead in an increasingly automated world. By exploring the top 10 trends in manufacturing and automation, we can gain insights into how these sectors will evolve, highlighting the importance of embracing change and leveraging new technologies to drive future growth.

The emergence of Smart Factories and Industry 4.0 technologies is revolutionizing the manufacturing sector by integrating advanced digital technologies into production processes. According to a report by McKinsey, companies implementing Industry 4.0 solutions can see productivity increases of up to 20%. These smart factories leverage the Internet of Things (IoT), artificial intelligence (AI), and big data to optimize operations, enhance efficiency, and reduce downtime. By utilizing interconnected systems, manufacturers can achieve real-time visibility into their processes, leading to more informed decision-making and streamlined workflows.

Furthermore, the adoption of automation and robotics is expected to rise significantly in the coming years, with a projection from the International Federation of Robotics indicating that the global operational stock of robots will reach 20 million by 2025. This surge in automation not only enables manufacturers to improve precision and speed but also allows for easier scalability in production to meet fluctuating consumer demands. As industries increasingly embrace these technological advancements, they will not only enhance productivity but also foster innovation, driving competitiveness in a rapidly evolving market landscape.

The integration of artificial intelligence (AI) in manufacturing processes is revolutionizing the industry, driving efficiency and innovation at an unprecedented pace. According to a report by McKinsey, AI could potentially create an additional $3.5 trillion to $5.8 trillion in value annually for the global manufacturing sector. This potential stems from AI's ability to optimize operations, enhance product quality, and facilitate predictive maintenance, which can significantly reduce downtime and operational costs.

Moreover, AI technologies such as machine learning and computer vision are transforming traditional manufacturing paradigms. A Gartner report indicates that by 2025, 75% of organizations will implement AI-driven automation solutions to improve performance and decision-making capabilities. These solutions not only streamline production processes but also enable real-time monitoring and data analysis, allowing manufacturers to respond swiftly to market changes and customer demands. The adoption of AI in areas such as supply chain management and quality assurance signifies a substantial shift towards smarter, more adaptive manufacturing environments, ensuring that companies remain competitive in an increasingly digital landscape.

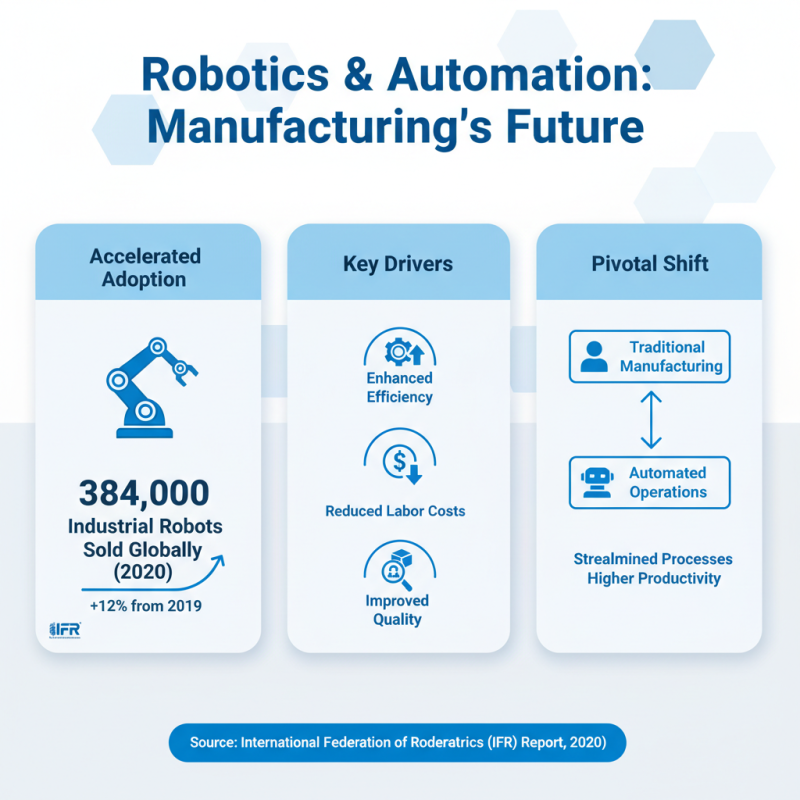

The adoption of robotics and automation in manufacturing has seen a significant acceleration, driven by the need for enhanced efficiency and productivity. According to a report by the International Federation of Robotics (IFR), global sales of industrial robots reached approximately 384,000 units in 2020, marking a 12% increase compared to the previous year. This growing trend highlights a pivotal shift as companies leverage automation technologies to streamline operations, reduce labor costs, and improve product quality.

Furthermore, a study from McKinsey & Company suggests that automating just a fraction of routine tasks could lead to productivity improvements of up to 30%. The manufacturing sector, which often involves repetitive tasks, stands to gain significantly from such efficiencies. With the integration of advanced robotics and automation systems, manufacturers are not only able to boost output but also enhance precision and adaptability in their processes. As industries continue to navigate labor shortages and supply chain challenges, the strategic implementation of robotics and automation is increasingly viewed as essential for maintaining competitive advantage and driving future growth.

Sustainability has become a pivotal focus in the manufacturing sector, driving innovations that prioritize eco-friendliness and resource efficiency. The rising awareness of environmental issues encourages manufacturers to adopt practices that minimize waste and reduce carbon footprints. Recycling and repurposing materials are becoming integral to production processes, enabling companies to turn by-products into valuable resources. This shift not only conserves raw materials but also aligns with consumer expectations for sustainable products, fostering a more responsible brand image.

Moreover, advanced technologies are leading the charge in sustainable manufacturing. Automation and AI facilitate real-time monitoring of energy consumption and emissions, enabling manufacturers to identify inefficiencies and implement corrective measures swiftly. Smart factories utilize data analytics to optimize supply chains and reduce waste, ensuring that resources are used as effectively as possible.

Additionally, the incorporation of renewable energy sources into production operations further supports sustainability goals while potentially reducing operational costs. As the manufacturing industry embraces these trends, it is setting a precedent for future practices that prioritize ecological balance alongside productivity.

The integration of data analytics in manufacturing is revolutionizing decision-making processes across the industry. By leveraging vast amounts of data generated from production lines, companies can gain valuable insights into efficiency, quality control, and overall performance. Advanced analytical tools enable manufacturers to identify patterns and trends that were previously obscured, allowing them to make informed decisions that enhance productivity and reduce operational costs. This data-driven approach not only optimizes workflows but also facilitates predictive maintenance, minimizing downtime and extending the lifecycle of machinery.

Furthermore, the impact of data analytics transcends operational metrics; it shapes strategic planning and market responses. Manufacturers can use real-time analytics to adjust production schedules, manage inventory levels, and respond to customer demands with agility. The ability to forecast market trends and consumer preferences empowers companies to innovate more effectively, launching products aligned with market needs. In an era where adaptability is critical, businesses that harness the power of data analytics can differentiate themselves, driving sustainable growth and maintaining a competitive edge in the evolving landscape of manufacturing.